snabba detaljer

Skick: Ny

Spänning: AC380V/220V

Mått (L*B*H): 1500*3040mm

Vikt: 980KGS

Certifiering: CE

Garanti: ett år

Tillhandahållen service efter försäljning: Ingenjörer tillgängliga för service maskiner utomlands

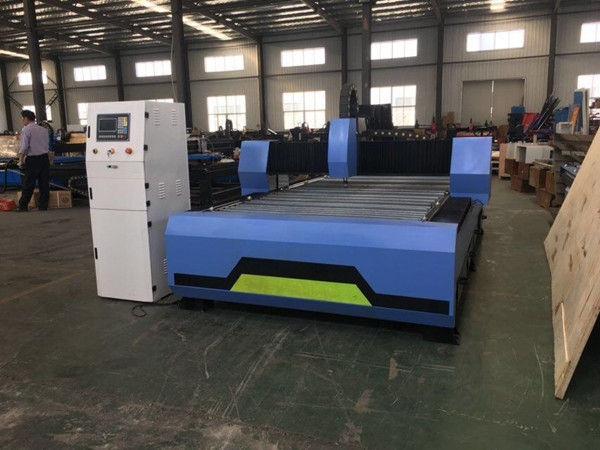

Produkt: Stor skärmaskin av rostfritt stål OP1530

Arbetsyta: 1500*3000mm

Bordsstorlek: 1700*3540mm

3-axlig styrmotor: stegmotor

Repeterbarhet: +/- 0,02 mm

Skärhastighet: 8m/min

Plasmaeffekt: 60A, 100A, 120A, 200Aetc

Arbetsspänning: 380v/220v,3 fras

Skärtjocklek: 0,3-40mm

Kommandospråk: G-kod

CNC Plasmaskärmaskin parametrar

| X,Y-axelrörelse | 1300 * 2500mm |

| Kroppsdimension | 1500*3040mm |

| Plasmakraft | 60A, 100A, 120A, 200A etc USA Hypertherm |

| Tabellstruktur | plasma special eldfast stålbord +6mm blad |

| repeterbarhet | +/- 0,02 mm |

| arbetshastighet | 8m/min |

| Max. Snabb resehastighet | 30m/min |

| Skärtjocklek | 0,3-40 mm |

| Traverssystem | Linjär styrning på 3-axlig |

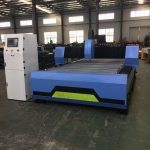

| Kontrollant | Startkontroll (med THC höjdkontroll) |

| arbetsspänning | 380V/220V,3 fras |

| kommandospråk | G-kod |

CNC Plasmaskärmaskin Funktioner

1 Svetsad svarvbädd av tjockväggprofilerad stål, mer solid och stabil.

2 Rimlig design av svarvbord, stålplattor av 10 mm tjocklek fixerade på svarvbord täckt av gjutet mantel med spikar. Stålplattor skadas inte ens under rasande flamma. Nivåskillnaden för hela plattformen med dubbel däck kvarstår i 0-1,5 mm.

3 Högkvalitativ stegmotor och racktransmission med hög noggrannhet. Låg ljudnivå, stabil och exakt koordinatrörelse.

5 DSP offline handkontroll; Programvara Type3 och Ucancam med automatisk materialbesparingsfunktion.

6 Standardkonfiguration: Fuli 100A plasmagenerator, som kan skära genom 10 mm metallplåt.

7 Bästa valet för alla typer av material med olika tjocklek och skärning av heterotyp typ.

Kapacitans höjdkontroll

Den avancerade linjära höjdkalibreringstekniken gör att skärmunstycket och skärbrädan är inom 3 ~ 30 mm i den automatiska höjdkontrollen i kapacitansläget;

Enkel och bekväm linjäriseringskalibrering

Funktionen för "En knapp för höjdkalibrering" garanterar att användaren under alla omständigheter bara behöver trycka på en knapp, han kan kalibrera den absoluta höjdmätningen och uppnå en linjär höjdmätning.

OMNI THC styrsystem kan

1. Utför hörnhastighetskontroll och höjdkontroll,

2. Brytpunktsåterställning, automatisk återställning av återställning och automatiskt brytpunktsminne,

3.Särskild bearbetningsfunktion för kort linje baserad på mjuk rörelse, mycket användbar för metallblankning såväl som reklam

4. Avancerad material lutande urladdning design. Alla färdiga arbetsstycken och fragment glider in i tunneln för säker och bekväm uppsamling.